6 Essential Lean Six Sigma Tools To Use to Maintain The Quality Standards High Techicy

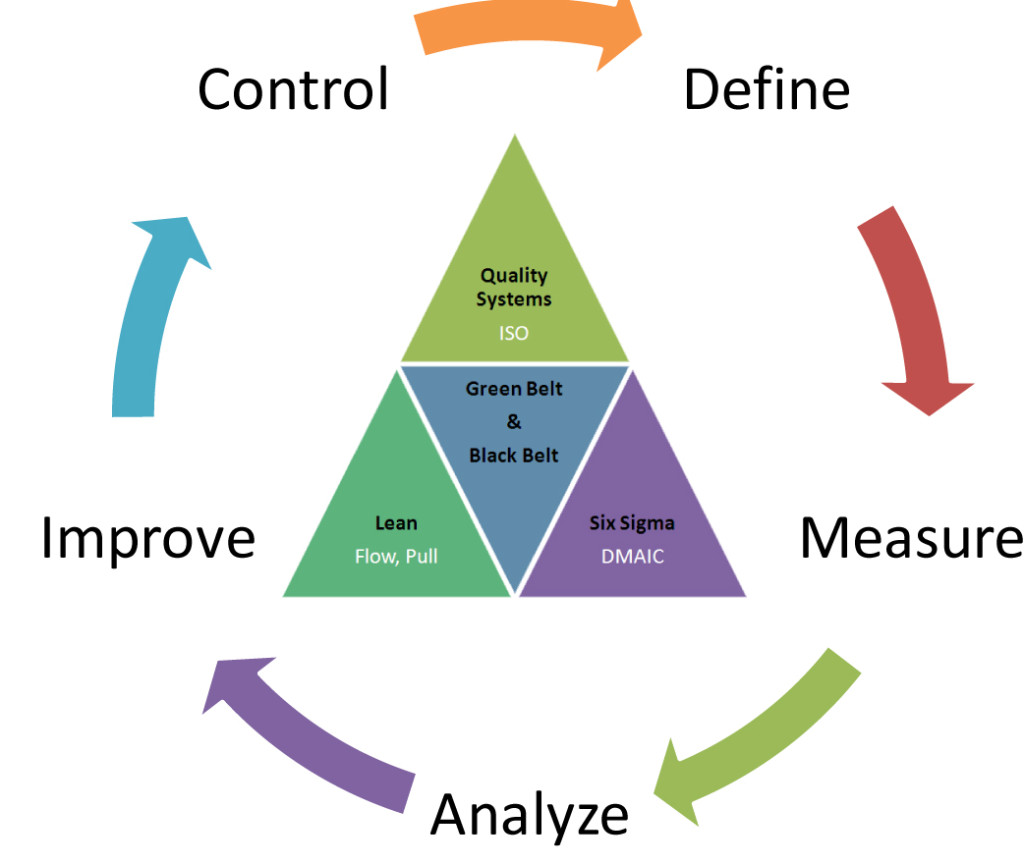

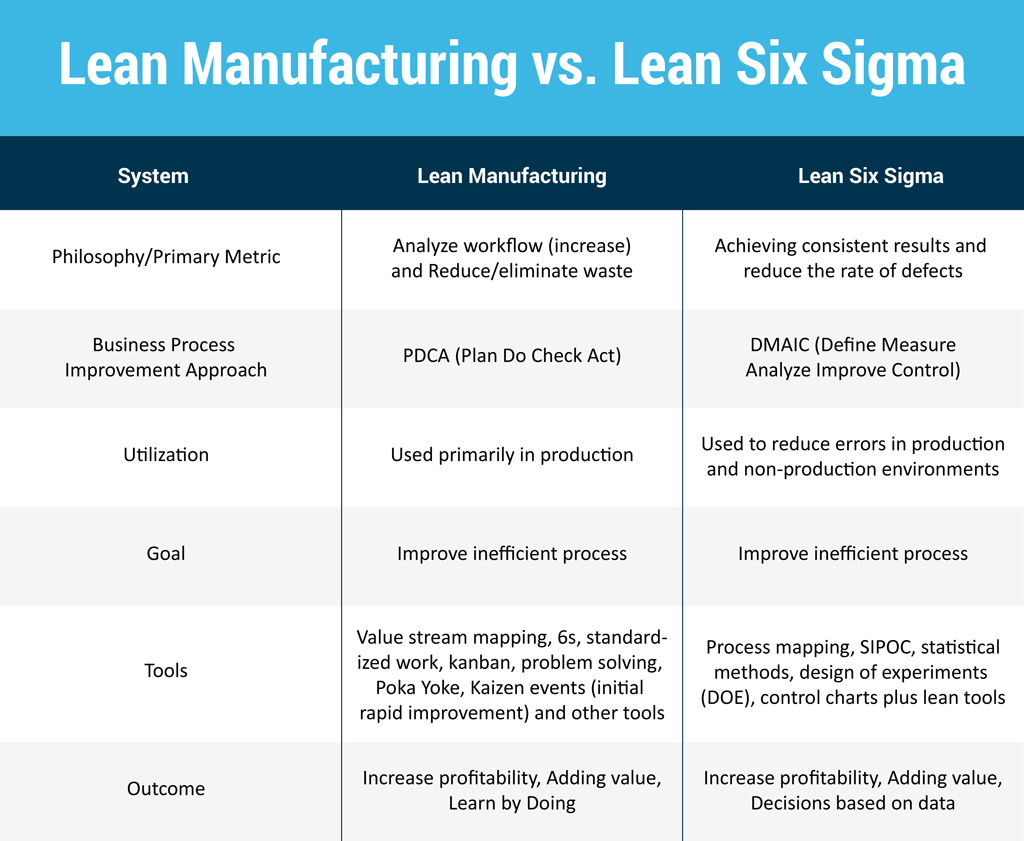

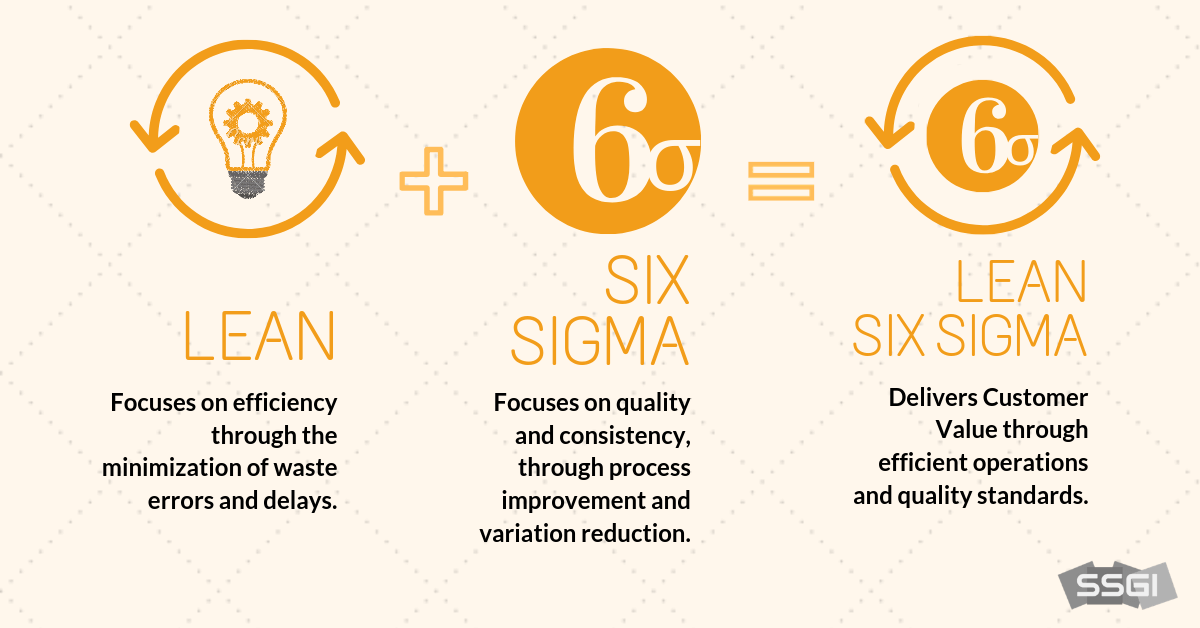

Lean Six Sigma brings together principles from lean manufacturing and Six Sigma. Lean manufacturing is a philosophy that emphasizes the elimination of waste and the improvement of production flow through collaborative team effort. Six Sigma is a data-driven methodology that uses statistical analysis and problem-solving tools to identify and eliminate defects as well as process variations.

What are the 5 phases of Lean Six Sigma? iCert Global

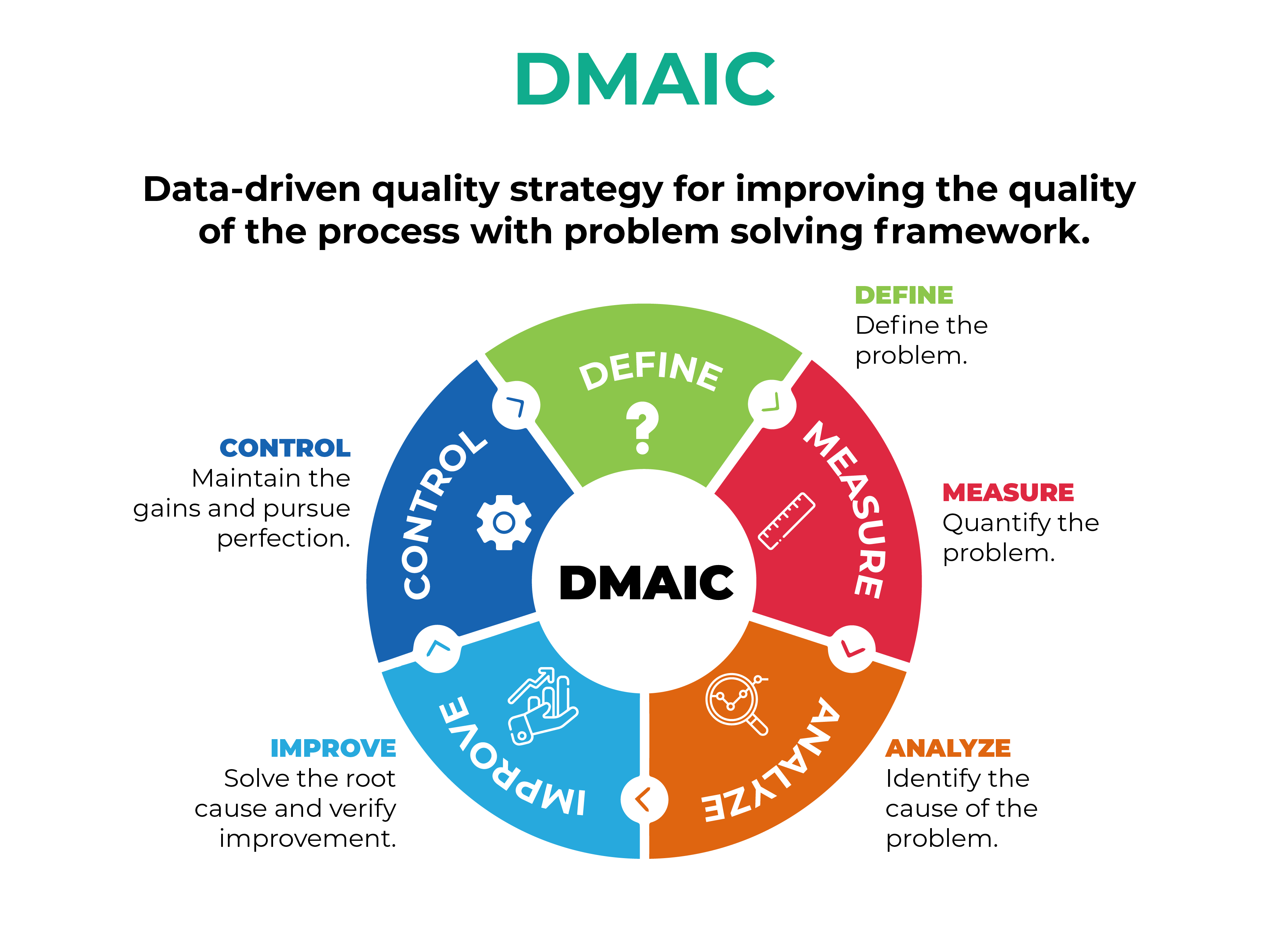

Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage.

Six Sigma 6S PowerPoint Diagram SlideModel

Learn about waste reduction, value stream mapping, and process improvement in our Lean vs Six Sigma guide. Helping businesses choose. Born out of the Japanese manufacturing industry, the Lean methodology teaches companies how to do more with less. It revolutionized Toyota's production process in the 1980s and has since become a globally.

Lean Six Sigma uma estratégia para vencer a competitividadeIPOG

Lean Six Sigma is a powerful approach that combines the principles of Lean manufacturing and Six Sigma quality management. It aims to eliminate waste, reduce variation, and improve process efficiency and effectiveness. By following a structured methodology, organizations can achieve significant improvements in quality, customer satisfaction.

Lean Manufacturing Principles From Concept to Implementation

Six Sigma (6σ) is a set of tools and techniques developed by Motorola engineer Bill Smith for process improvements. The philosophy behind Six Sigma is to identify, remove/improve the processes that cause defects in manufacturing or business processes. It aims to remove the variability in production and processes to bring about a highly.

Quality Systems Enhancement Lean Six Sigma (6σ) Management

Lean Manufacturing and Six Sigma. Make a fundamental change in how your organization thinks. Lean is a practice that improves processes and reduces waste by harnessing the drive of the total organization. Six Sigma is a set of techniques and tools for process improvement that seeks to improve quality and remove the causes of defects in.

Lean Six Sigma Principles and Tools and Their Applications

Lean Six Sigma is a systematic approach to reduce or eliminate activities that do not add value to the process. It highlights removing wasteful steps in a process and taking the only value added steps. The lean six sigma method ensures high quality and customer satisfaction in the manufacturing. The main purpose of this chapter is to explore the Lean Six Sigma (LSS) in the manufacturing sector.

Lean Manufacturing VS Six Sigma ! Difference between lean manufacturing & six sigma YouTube

Lean Manufacturing and Six Sigma, each powerful in its own right, can offer businesses unparalleled advantages when understood and implemented correctly. Whether adopted individually or in tandem, their principles can lead to heightened efficiency, quality, and customer satisfaction. As industries evolve, the significance of these methodologies.

Infographic Seven Wastes of Lean Six Sigma

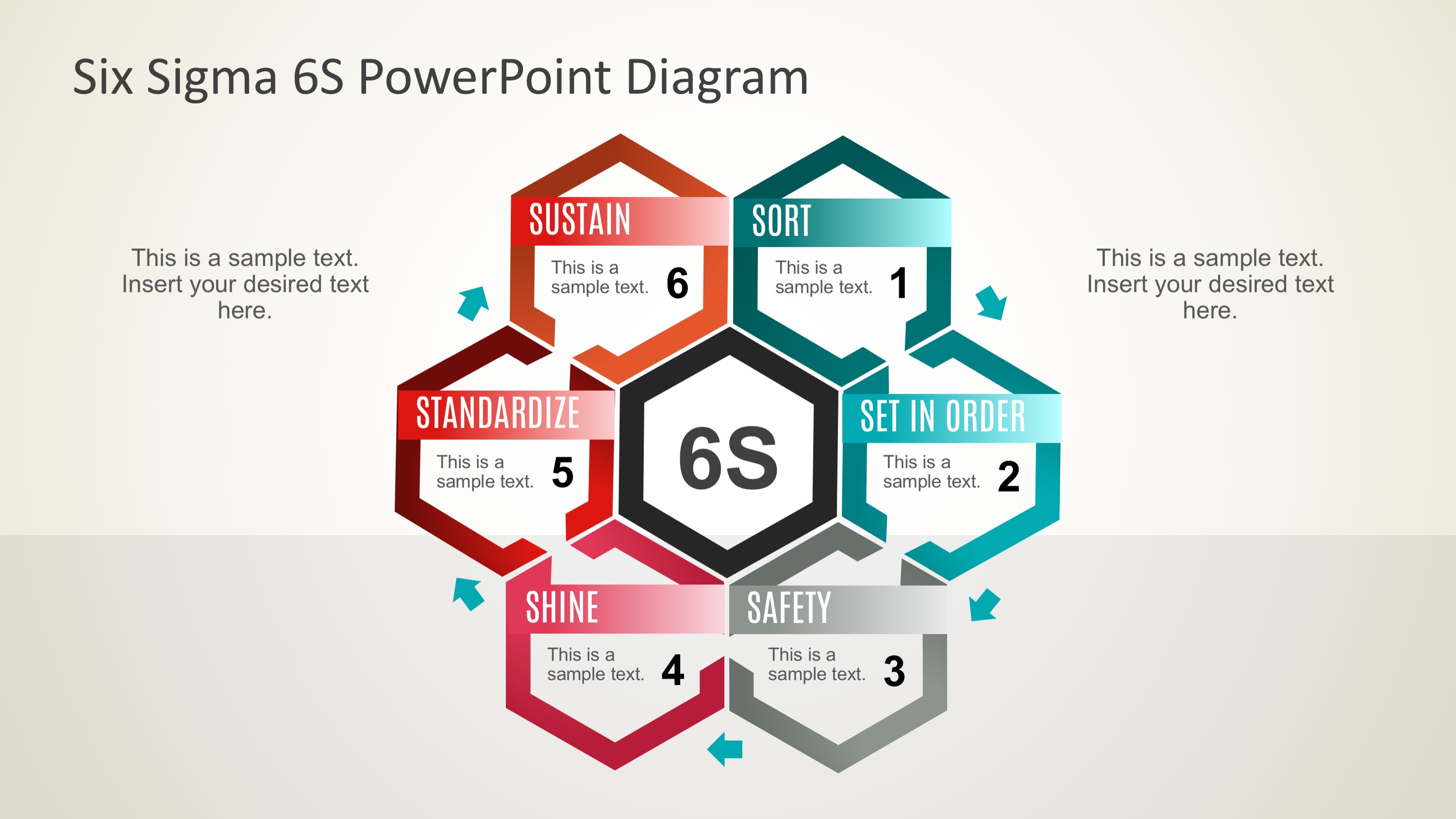

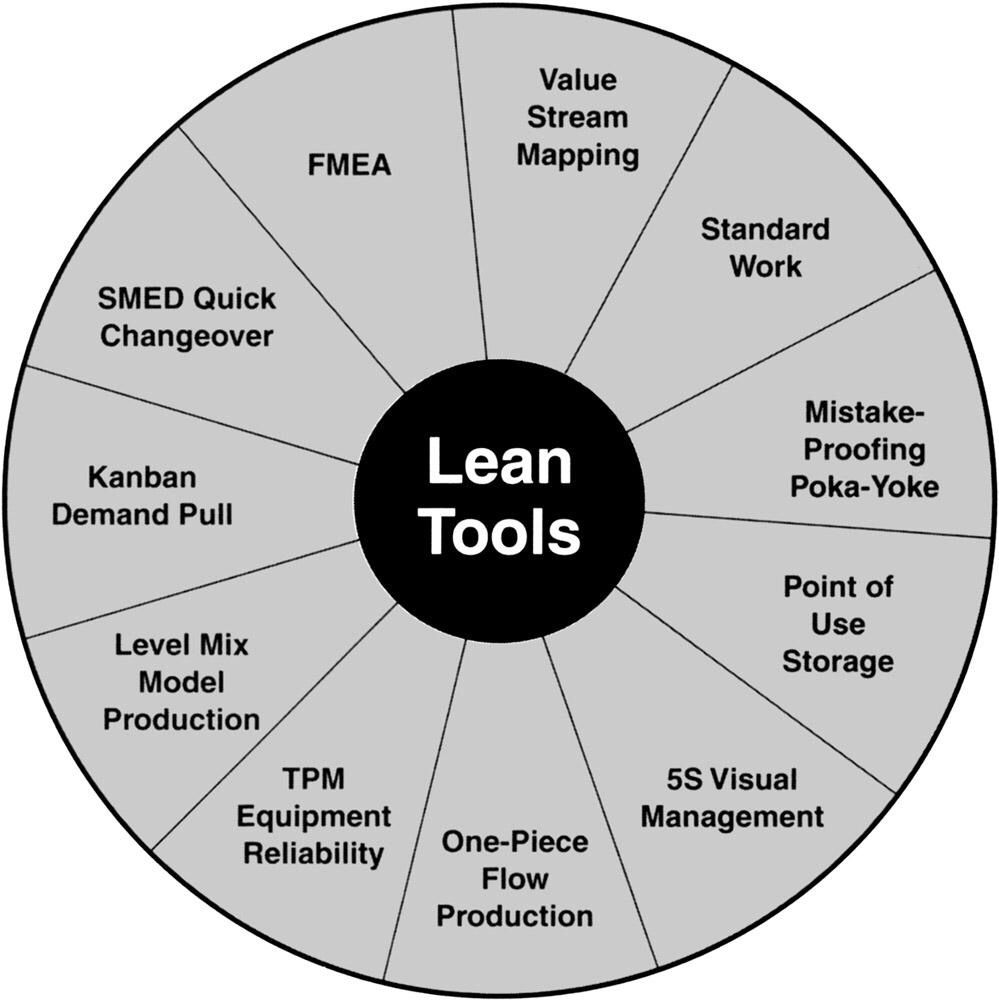

5S Workplace Organization and Lean Operations. The 5S system is a lean methodology focused on workplace organization and standardization. The 5 Steps are Sort, Straighten, Shine, Standardize, and Sustain. Implementing 5S reduces motion waste, waiting times, and other inefficiencies caused by disorganized work areas.

What’s the Difference Between Lean Six Sigma and Six Sigma? SSGI

Six Sigma (6σ) is a set of techniques and tools for process improvement.It was introduced by American engineer Bill Smith while working at Motorola in 1986.. Six Sigma strategies seek to improve manufacturing quality by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes.This is done by using empirical and statistical quality.

Lean Six Sigma Where Waste Reduction Meets Quality Improvement Inductive Automation

About Lean Six Sigma Institute. At Lean Six Sigma Institute, we are committed to transforming the manufacturing industry by applying Lean Six Sigma methodologies. Our customized programs address the unique challenges and opportunities within the manufacturing sector. 70k+ certified students. 400+ Implementation Projects. 500+ million (USD) saved.

Lean Manufacturing Inductive Automation

Here are some of the key benefits: Increased efficiency and reduced waste: Lean Six Sigma focuses on identifying and eliminating waste in all areas of a manufacturing process, resulting in increased efficiency and lower costs. Improved quality: Six Sigma is a quality management approach that aims to reduce defects to a minimum, resulting in.

Everything you need to know about the Six Sigma Green Belt

Like the lean manufacturing approach, Six Sigma uses process maps and workflow charts in this effort. Develop a plan - Any inefficiencies identified in step 2 can be subjected to processes like the 5 Whys [link to glossary page] to understand the nature of the problem and come up with a plan that addresses it.

Lean Six Sigma Overview, Benefits and Tools YouTube

Lean Six Sigma is a managerial approach that combines Six Sigma methods and tools and the lean manufacturing/lean enterprise philosophy, striving to eliminate waste of physical resources, time.

7 Lean Six Sigma Methodology Can Speed Up Your Business Growth

Daniel Croft. June 20, 2023. Learn Lean Sigma. Guide. Guide: Fundamentals of Lean Six Sigma. Lean Six Sigma is a powerful operational improvement methodology that synergizes the efficiency-focused Lean principles with the quality-centric Six Sigma approach. Originating from the best practices of Japanese manufacturing, particularly Toyota's.

Seis Sigma ou Six Sigma O que é e como implementar

The methodology is versatile enough to find applications in diverse sectors, from manufacturing to services. Lean Six Sigma fosters a collaborative approach, engaging team members and relevant stakeholders throughout the process. The emphasis on data collection and analysis supports informed decisions, while the continuous improvement culture.

.